2.0mm Medium Link G316 Stainless Steel Chain TRADE PACKS

2.0mm Medium Link G316 Stainless Steel Chain is the lightest general purpose chain. This chain suits light rigging and Shop Fitting.

Click Here for 1M lengths and other sizes

Description

2.0mm Medium Link G316 Stainless Steel Chain is the lightest general purpose chain. This chain suits light rigging and Shop Fitting. 2.0mm Welded Medium Link G316 Stainless Steel Chain (Marine Grade) has virtually no stretch and excellent flexibility. The chain surface is electropolished. As a result, it best used with similar G316 fittings which include quick-links, shackles, and spring hooks. All 2.0mm fittings suit this chain. Tensile Strength (MBS) = ~180kg

Usage: This is a very light and strong chain making it easy to work with and conform without stretch. Wire and fitting size also affect desired chain size. Anticipated load determines optimum chain size. Additional factors to consider are the dimensions of the links and the material of related fittings. Additional uses include: Picture (statue?) Hanging, Shop Fitting, Shade Sails, Trellis structuring, ‘Green Wall’ construction, Rigging Slings, Theatre Production Infrastructure – Stage Lights, Curtains, & Prop Construction.

Length of Wire: Use combinations of the offered lengths to get the desired total length. For example – choose a quantity of “8” of the 1M length to select a single length of 8 Metres. We cut and ship all Chain orders as a single length. As a result, each wire order is packaged as a coil or a reel depending on length and all are factory wrapped and sealed. A requirement of less than 100M on a reel needs a special order (please phone first).

Quality: All Low Cost Wire products meet our strict ISO Quality Standards. Our chain and wire rope delivers the optimal balance between high tensile strength, fatigue resistance, abrasion resistance, and structural stability. Finally, our process provides a special treatment for a bright and smooth surface on the wire and cable. As a result, this delivers a truly top-shelf, long lasting product that will look new for ages…

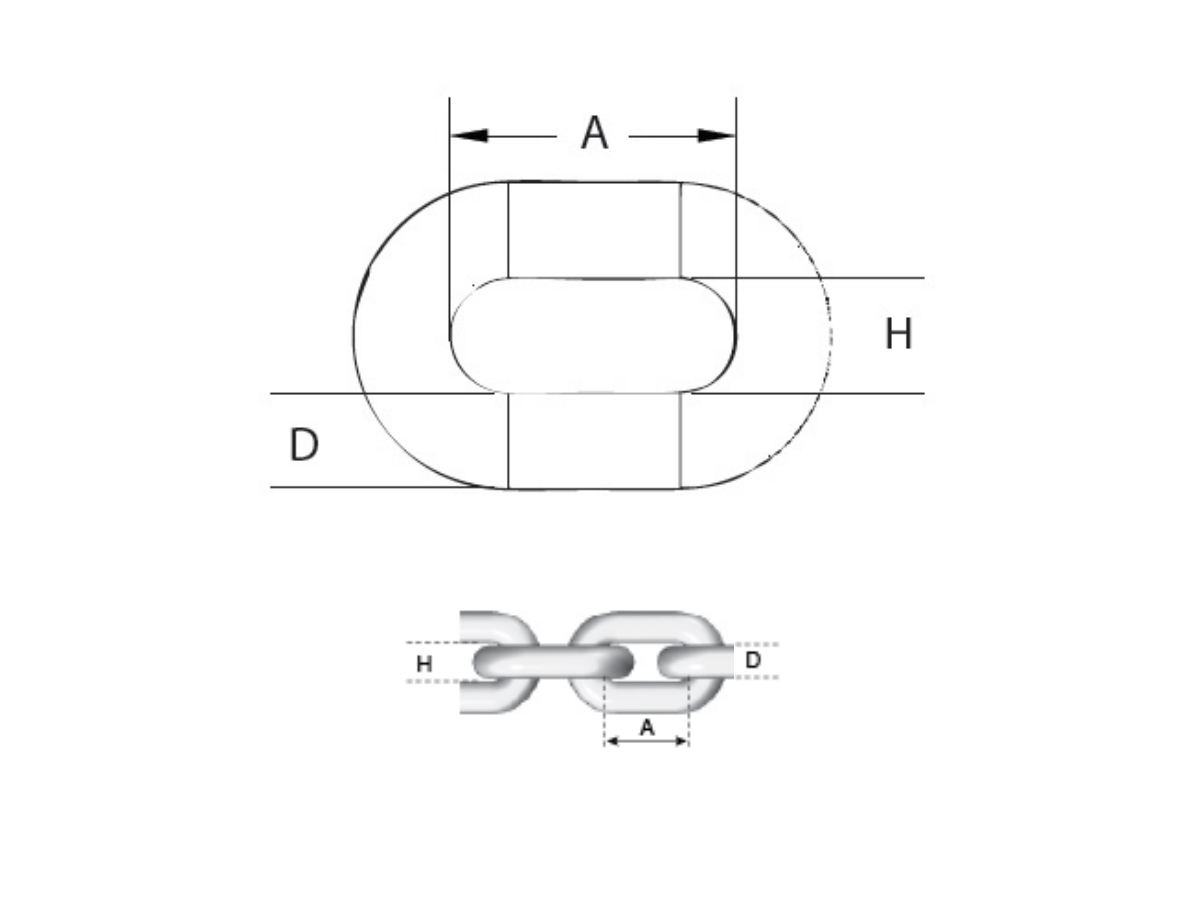

Dimensions: A = ~14.7mm D = ~2.0mm H = ~4.76mm

Additional information

| Length | 10M, 100M |

|---|---|

| Item Diameter | 2.0mm |

| Material | Stainless Steel |

| Grade | 316 / A4 |

| Flexibility | High |

| Dimensions | A = ~14.7mm |

| Brand | Low Cost Wire |

| Structure / Construction | Medium Link |