Compact Nutsert Tool

Our Compact Nutsert Tool is industry fabrication quality and IMHO – one of the best hand tools around. As well, this tool has the improved central tempered shaft with knurled nut installed to Non Standard Cast Factory Fitted Equipment – made stronger to last longer.

Description

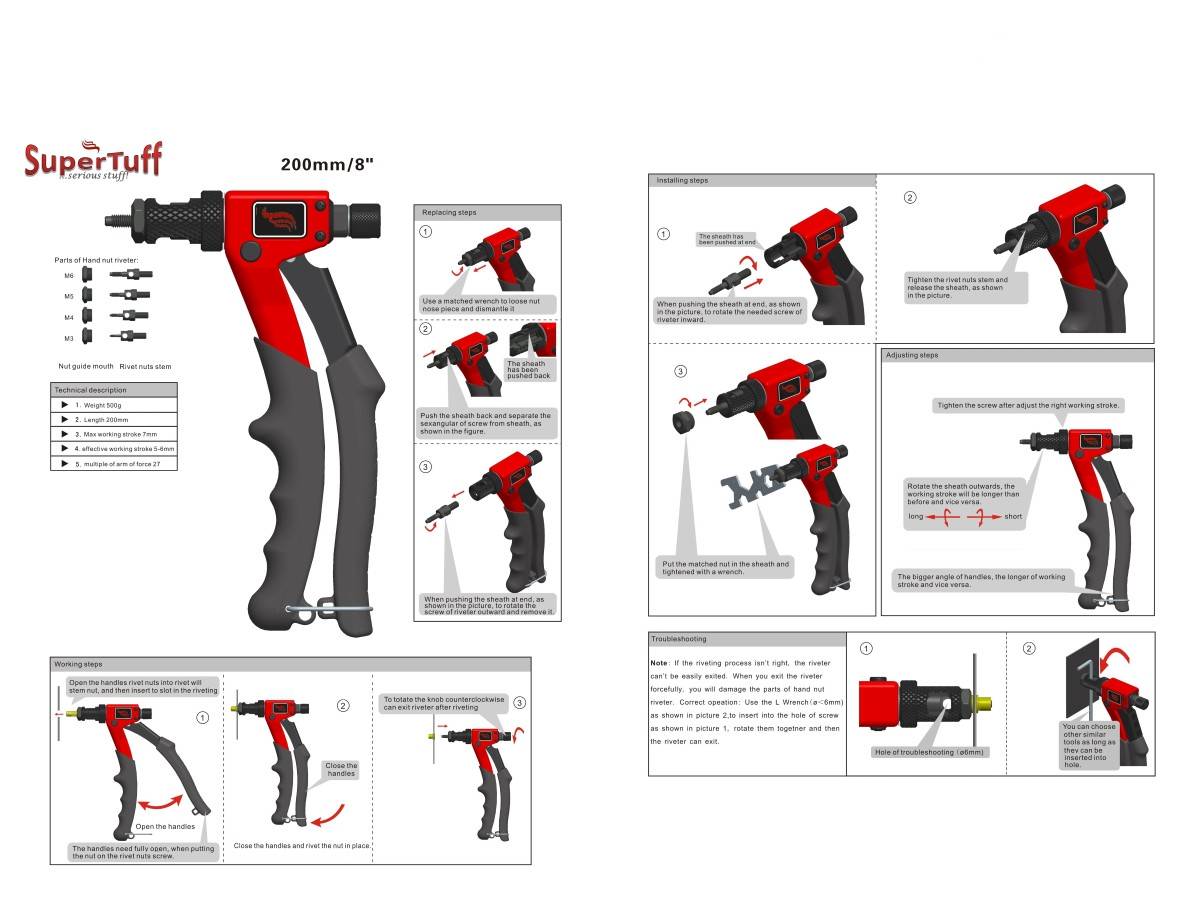

Compact Nutsert Tool

Our Compact Nutsert Tool is industry fabrication quality and IMHO – one of the best hand tools around. As well, this tool has the improved central tempered shaft with knurled nut installed to Non Standard Cast Factory Fitted Equipment – made stronger to last longer. The Light Duty Compact Nutsert Tool is well designed with reliable, solid construction and a complete set of mandrels for light duty applications (either UNC or Metric). These Mandrels are what are required to ‘set’ a nutsert into a panel.

Optional and complementary products for this tool include:

- Blow Mold High Impact Custom Case with Rivnut and Mandrel Storage, and

- M-35 3mm-12mm (1mm steps) Step Drill

Features & Benefits:

- Overall length of the tool (200mm / 10″) provides excellent leverage

- Compact (200mm / 10″) for getting into those small areas and making it easy to use

- Includes stroke adjustment feature which eliminates errors

- Unique one handed operation

- Easy release – just twist the knurled knob to unscrew the Rivet Nut from the Tool’s Mandrel

- Shock-proof design with ergonomic handles to eliminate vibration

- Rubberized ergonomic handles make it easier to use for extended periods

Specifications:

- Overall length of the tool (200mm / 10″) provides excellent leverage

- Weight 500g

- Interchangeable Heat Treated Mandrels

- Working stroke 6mm

- Maximum effective working stroke 5mm

- Leverage from tool multiplies arm force by a factor of 20

Contents:

- Compact Nutsert Tool with Installation Depth adjustment Nose

- Multi Purpose Open End Spanner to suit the various nuts for interchangeable mandrels

- Instruction sheet.

- Available Mandrel Sets

- Metric –M3, M4, M5, M6 RH Mandrels

- Imperial –6-32, 8-32, 10-24, 1/4-20 RH Mandrels

Additional information

| Weight | 1.6 kg |

|---|---|

| Mandrel Sets | RHT (M3, M4, ,M5, M6), RHT(6-32, 8-32, 10-24, 1/4-20) |

| Thread | 6-32, 8-32, 10-24, 3/16"-24, 1/4"-20, 5/16"-18, 3/8"-16, M3 RHT, M4 RHT, M5 RHT, M6 RHT |

| Material | Mild Steel |

| Brand | Low Cost Wire |

| Style | Nutsert – Tool |

| System | Imperial UNC, Metric Coarse |