The Fill factor (f) gives guidance as to the compressability of wire rope during the swaging or crimping process.

Definition

The Fill Factor (f) is defined as the ratio between the Metallic Cross sectional area and the Measured Cross Sectional Area.

- the Metallic Cross sectional area is the sum of the nominal metallic cross sectional area (A) of all of the wire rope components – including the core plus the strands made up of wires in the rope and

- the Measured Cross Sectional Area is the circumscribed area (Au) of the rope based on its nominal diameter (D) when measured correctly with calipers.

The fill factor is important when selecting the ferrule or fitting size. Since you are constructing a ratio that represents the amount of metal in a wire rope – it is clear that the Wire Rope Specification core of a rope will greatly affect its fill factor. With regard to cores: Fibre Core (FC) Wire Ropes, Independent Wire Rope Core (IWRC), and Independent Wire Core (IWC) have increasing fill factors. With regard to Wires: the greater the number of independent wires, the less “space” in the wire and the higher the fill factor.

Overall, the general guideline is: The higher the fill factor, the larger the ferrule.

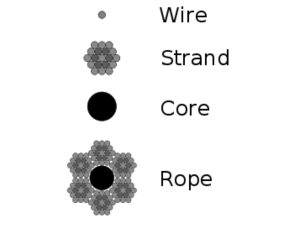

Wire Rope Make up

Wire Rope has 3 components as represented by the diagram. The combination of these components results in the structure of the wire and greatly affects its characteristics.

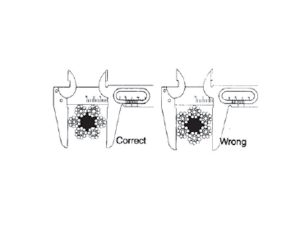

How to Measure Wire Rope

It is critical to measure wire rope Diameter (D) across the top of the strands – not in the ‘valleys’- and that means that the top of the strands are between the jaws of the calipers