In Australia Balustrade constructions are government by the National Construction Code 2019. This code provides guide lines for balustrade construction, materials and heights restrictions. A balustrade is defined as a rail and its balusters, including timber, metal and glass. In this summary, we will deal with the use of wire as the fencing medium.

The NCC remains largely unchanged since 2005 and a copy of the NCC is available from the Federal Government. However, for your convenience, a summary is available through this post and here is a link to the tables.

Planning

One of the first steps when planning your wire balustrade is to have an understanding of the different wire types that are available, the most common wires used for balustrades are 316 Stainless Steel 3.2mm 1 x 19, and 3.2mm 7 x 7 wire (generally described as 3mm wire).

3.2mm refers to the diameter of the wire, and 1 x 19, and 7 x 7, refers to the structure of the wire

- 1 x 19 wire is

- made up of 1 single wire with 19 strands,

- low flexibility making it very well suited for wire balustrades with hydraulically swaged terminals,

- brutally hard to use with Nickel Coated Copper Swages and Thimbles,

- only suitable for hydraulic swaging where as

- 7 x 7 wire is

- made up of 7 wires with 7 strands within each wire,

- mid level flexible wire making it an acceptable choice for balustrades

- easy to use with Nickel Coated Copper Swages and Thimbles,

- only suitable for hand swaging

Can I use a wire balustrade solution around a pool?

YES: and you must use vertical wire to both comply with the regulations and to prevent climbing. The technical regulations are a bit different (top rail height in particular is 1.2m high when measured from the outside, and any boundary fences that make up the pool fence must be at least 1.8m high). Then there are some Gate regulations – but it is VERY doable – <CLICK HERE FOR MORE DETAIL> Just follow the basic guide for a Vertical Wire Solution and you’ll ‘be right’

Will the regulations apply to my Deck/Veranda project?

NO: If your structure is an existing and you are refurbishing or repairing.

You are pretty much in the clear as putting up wire on an existing structure is like giving it a fresh coat of paint. But check that comment about liabilities…

YES: If your structure is new – then it is highly advisable to comply with the regulations. Simply because its better to build an asset, than a liability. Now we have to decide if Vertical or Horizontal wires are required.

Horizontal wire is acceptable if the deck (surface) has a drop off greater than 1 meter (at some point) but always a drop off less than 4 meters to the area below

Vertical wire is required if the deck (surface) has a drop off greater than 4 meters (at some point) but acceptable in all other circumstances

However, It may be possible that your wire balustrade will not need to comply with NCC regulations – Below are some common situations and how you can deal with them.

Exceptions:

The deck has a drop off less than 1 metre to the area below

Again, you are pretty much in the clear and unaffected by the regulations. If the bottom of your deck is no more than 1 meter off the ground at any point, then the regulations will not apply to you. It is up to you to decide the most appropriate level of safety, wire spacing and how many support posts you use on your balustrade.

What do I have to do to comply with the NCC Regulations?

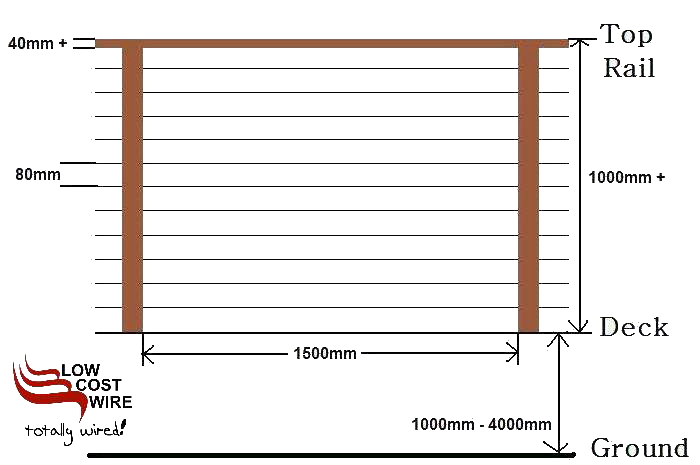

The Horizontal Wire Solution: This advice applies to both Timber and Metal rail/post constructions. You will need a top rail, plan your installation around straight-line sections (up to 20M), and plan to fit your wires and posts according to NCC Regulations. And there is a table below for doing horizontal wire balustrades. But the simplest guidelines (for All wire structures…) that work EVERY TIME are:

- Keep your wires ~80mm apart, and

- Keep your posts <= 1.5M apart.

This means that a balustrade with wire support posts every 1500mm, and a top rail (with 40mm thickness) and a height of 1 meter (960mm to the underside of the handrail, will require 11 runs/kits of wire. When installed at 80mm apart – the prescribed tension/deflection will be easily achieved.

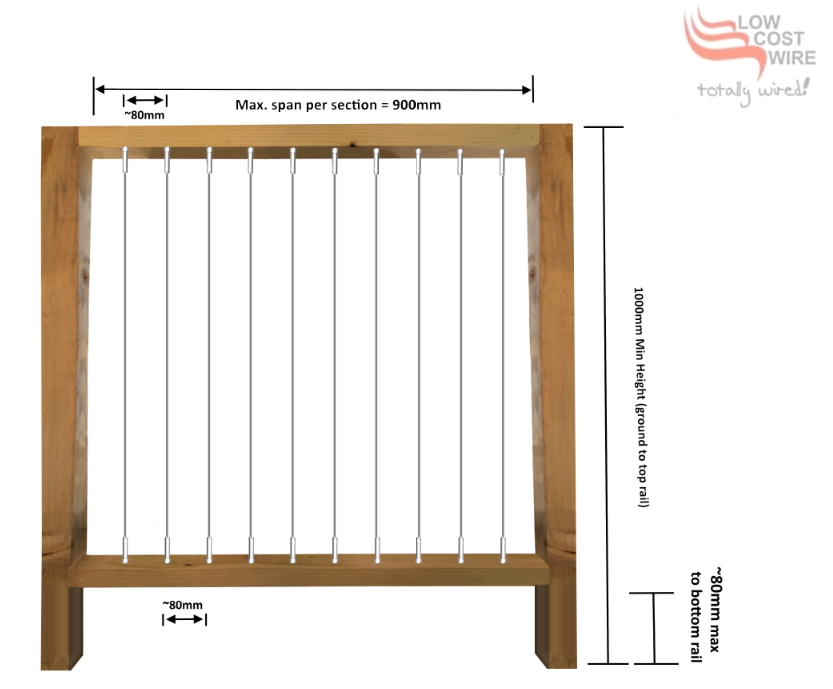

The Vertical Wire Solution: This advice applies to both Timber and Metal rail/post constructions. You will need a top rail and a place on the bottom into which to fasten the fittings. There are many ways to achieve this – but this advice is based on our commercial experience… The top rail needs to be thick enough to accept a 40mm thread. T-Section construction is also recommended for maximum rigidity. For bottom fastening, we recommend a bottom rail (at least 40mm thick) spaced 80mm above the surface. Plan your installation around straight-line sections with 1M centers (~900mm between posts), and plan to fit your wires and posts according to NCC Regulations. And there is a table below for doing horizontal wire balustrades. But the simplest guidelines (for All wire structures…) that work EVERY TIME are:

- Keep your wires ~80mm apart, and

- Keep your posts ~900mm apart.

This means that a balustrade with wire support posts every 900mm will require 10 runs/kits of wire in each vertical section. When installed at 80mm apart – the prescribed tension/deflection will be easily achieved.