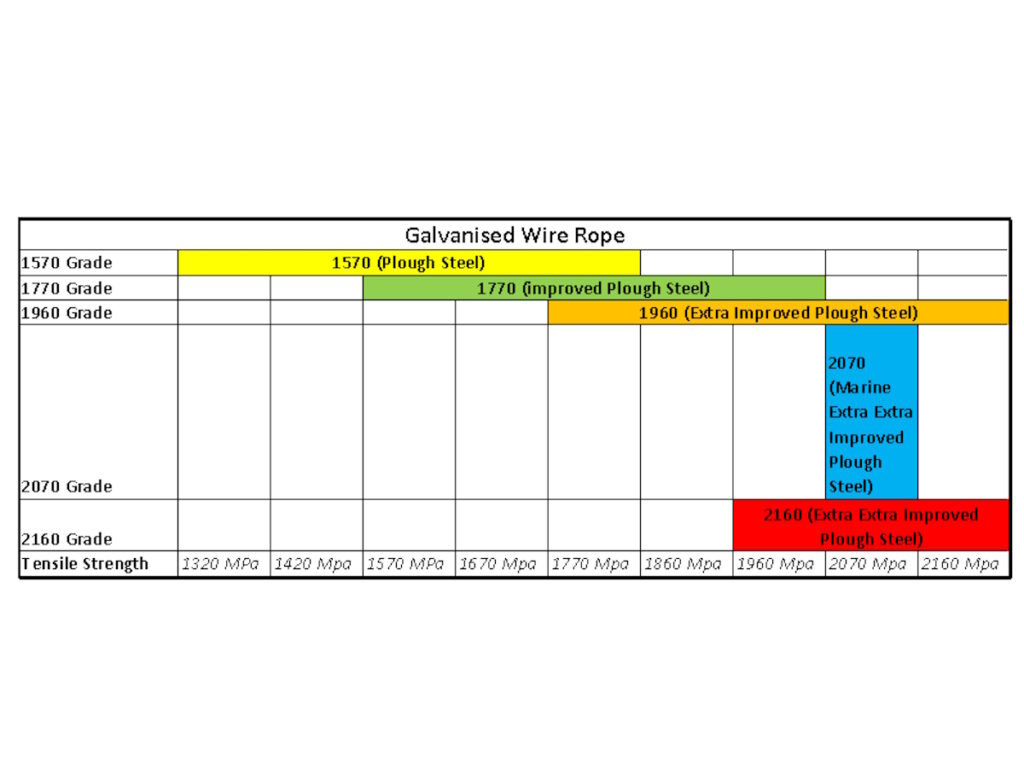

Galvanised Steel Wire Rope is graded by its strength. However, there is not an accepted international standards body that has specified the alloys and exact performance standards that apply to a ‘particular’ grade of galvanised wire rope. (NOTE: this is in direct contrast so how Stainless Steel Wire Rope is graded). So with no accepted standard grading criteria, the exact terms and comparability of different Galvanised Wire Rope is difficult.

Historically, three primary grades of Galvanised Steel Wire Rope are Plow steel, Improved Plow steel, and Extra Improved Plow Steel. Marine Grade is a recent addition. These terms are in common use in Europe and reflect the strength of the wire in N/mm2. Australia and North America tend to use terms that directly describe the strength of the wire in N/mm2. Virtually all grades are available in a number of structures.

Plow Steel Galvanised Wire Rope is your basic cheap wire rope. It is certainly tough and strong, but definitely the ‘economical’ option. This steel has a tensile strength of 1570 N/mm2 and can be referred to as G1570.

Improved Plow Steel Galvanised Wire Rope is the most commonly used rope. Improved plow steel is stronger, tougher, and more resistant to wear and corrosion than plow steel. This steel has a tensile strength of 1770 N/mm2 and can be rerred to as G1770

Extra Improved Plow Steel (EIPS) Galvanised Wire Rope is used in the manufacturing of wire ropes for installations, where high rope strength is required and conditions of use permit its use. Some applications such as mine shaft hoisting, where increased tonnages on existing skips and drums can be tolerated, and where conditions such as sheave and drum diameters are favorable to its use – this grade of Galvanised Wire has distinct advantages. This steel has a tensile strength of 1960 N/mm2 and is referred to as G1960 or G1970

Marine Grade Galvanised Wire Rope is used in wire rope installations where maximum rope strength, durability, and corrosion resistance is required and conditions promote its use. Applications in highly aggressive environments – such as mines, petrochemical plants, or marine environments are favorable to its use. This steel has a tensile strength of 2070 N/mm2 and is referred to as G2070 or G2160.