3.2mm/5.0mm 7×19 Black Coated HS24 Tool Swages Thimbles Wire Use Kit

$2.93 – $88.57 Inc GST

3.2mm/5.0mm 7×19 Black Coated HS14 Tool, Wire, Swages, Thimbles – Wire Use Kit groups tools and fittings required for PVC Coated 3.2mm Stainless Steel Wire. This kit provides the basics components – to work with the wire leaving the coating on.

Description

3.2mm/5.0mm 7×19 Black Coated HS14 Tool, Wire, Swages, Thimbles – Wire Use Kit groups tools and fittings required for PVC Coated 3.2mm/5.0mm Stainless Steel Wire. This kit provides the basics components – to work with the wire leaving the coating on. Basically you need:

- Wire (of some length) which sort of depends on the project.

- Ferrules (also called crimps or swages). These fasten either the wire to itself (and form a loop – 1 required per loop) or complete a splicing operation (at least 2 required per lap-splice),

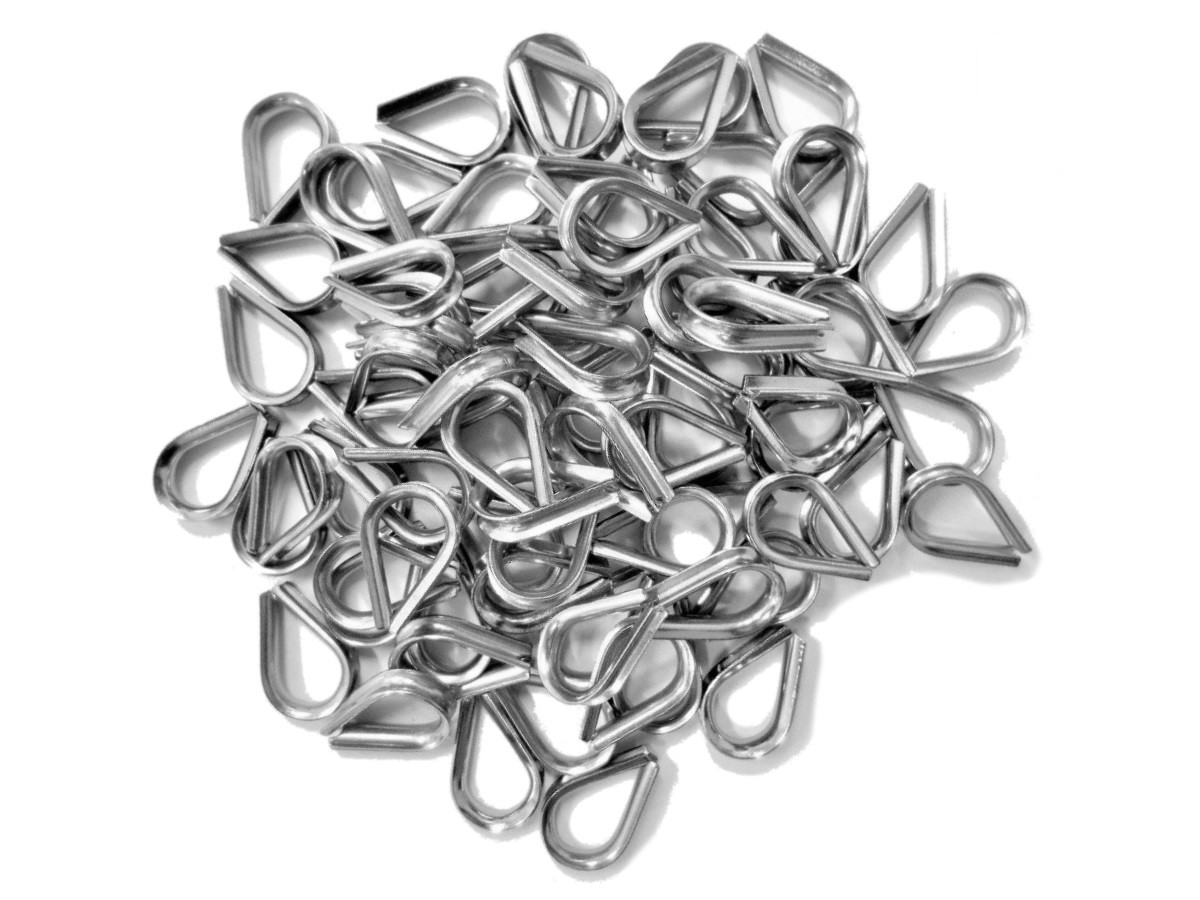

- Thimbles (also called eyelets) as these are the reinforcing strip of stainless steel metal that goes inside of a terminal loop (called a Hard-Eye with a thimble and a Soft-Eye without a thimble,

- Swager (or swaging or crimping or welding tool) These are available in either a hydraulic form or a mechanical form

- Heatshrink to for a neat and waterproof connection, and a

- Cutter which simply cuts the wire,

Usage: Using the 3.2mm/5.0mm 7×19 Black Coated HS14 Tool, Wire, Swages, Thimbles – Wire Use Kit is easy. Simply cut the wire to length – each ‘eye’ takes about 90mm of wire. When leaving the coating on, use 5.0mm ferrules and thimbles. Just slip one end into a ferrule, make a loop and slip the end back into the ferrule – without a thimble this is a soft eye. We recommend using a thimble inside the loop to form a hard eye as the thimble distributes the load on the loop. Additionally, the thimble limits the radius through which the wire is pulled – thereby maintaining the MBS and load characteristics of the wire.

Quality: All Low Cost Wire products meet our strict ISO Quality Standards. Firstly, our products achieve the optimal balance between high tensile strength, fatigue resistance, abrasion resistance, and structural stability. Secondly, that long experience with wire rope manufacturing enables the design and manufacture of aesthetically beautiful and functional products. Finally, our products have a special treatment for bright and smooth surface of wire and cable to deliver a truly top-shelf, long lasting product that will look new for ages…

Wire Use Kits are also available for different sizes of Wire Rope.

Additional information

| Wire Diameter | 3.2mm, 5.0mm |

|---|---|

| Connection Style | Manual Swaging |

| Brand | Low Cost Wire |

| Style | Kit – Wire Use |

| Material | Stainless Steel |

| Coating | PVC |

| Color | Black (Opaque) |