Wire Rope Structures

Wire Rope Structures govern flexibility – within a given diameter – and to a much lesser degree the MBS (Minimum Breaking Strain) MBL (Minimum Breaking Load) interpreted as Safe Working Load or “Breaking Strain” of the wire. See also our Wire Rope Specifications for various sizes and structures of Wire.

Rest assured that there are many OTHER factors also involved. Generally, the more wires twisted to make a strand, the more flexible is the overall wire rope because it deforms/bends without damage. Relevant terminology involves Wire, Strand, Core, and Rope

Wire Structures

The structure of a wire rope consists of two parts – Strand and Cable where these are related because Cables are built of Strands around a Core. If the core is a single wire, then the Wire Rope is designated S+IWRC (Steel Independent Wire Rope Core). If the core is a multifiber strand, then the Wire Rope is designated WSC (Wire Strand Core). If the core is non-metal, then the Wire Rope is designated FC (Fiber Core).

In general, these common wire strand constructions are the starting point for wire rope. They are groupings of fibers:

- 1×1 which indicates a single fiber. This is the lowest flexibility wire and is considered can be used in push/pull applications.

- 1×3 which indicates a collection of 3 individual fibers which are grouped together then – twisted together to form a single strand. This is a low flexibility strand and is considered can be used in push/pull applications.

In general, common wire cable constructions are groupings of strands:

- 1×7 which indicates a collection of 7 individual fibers grouped together then – twisted together to form a single strand. In a 1×7 strand, six outer wires are laid around the center wire. This is a medium flexibility strand and more flexible than the 1×3, it is also used for push/pull applications.

- 1×19 which indicates a collection of 19 individual fibers grouped together then – twisted together to form a single strand In a 1×19 construction, 12 outer wires are laid around a 1×7 center. This construction is a high flexibility strand and even more flexible than the 1×7 and can still be used in push/pull applications.

- 3×7 which indicates a collection of 21 individual wires which are grouped as 3 strands of 1×7 wires each – twisted together to form the cable. This is a medium flexibility wire and is considered ‘general purpose’ and offers an economical approach.

- 7×3 which indicates a collection of 21 individual wires which are grouped as 7 strands of 1×3 wires each – twisted together to form the cable. In a 7×3 cable, six 1×3 strands are wrapped around a 1×3 center. This cable has many of the same properties as the 3×7 but is much smoother. 7×3 is a medium flexibility wire and a common construction for applications where a jacketed cable is needed.

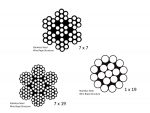

- 7×7 which indicates a collection of 49 individual wires which are grouped as 7 strands of 1×7 wires each – twisted together to form a single strand. In a 7×7 cable, six 1×7 strands are wrapped around a 1×7 center. This construction is one of the most commonly used in the construction industry. 7×7 cable is known for its flexibility and high cycle life. This is a medium flexibility wire and is considered ‘general purpose’ and offers an economical approach.

- 6×19 indicates a collection of 114 individual wires grouped as 6 sub-strands of 19 wires each. Consequently, 6 wire bundles of 19 wires twisted together form a single strand. Since a single Fibre forms the core, this structure is FC. This is our most flexible wire Galvanised Wire. Often for use in event rigging or small cranes or winches rather than balustrade construction.

- 6×36 indicates a collection of 216 individual wires grouped as 6 sub-strands of 36 wires each. Consequently, 6 wire bundles of 36 wires twisted together form the wire rope. Normally only used in very thick wire (generally > 6.0mm).This is our most flexible wire for use in rigging or small cranes or winches.

- 7×19 which indicates a collection of 133 individual wires which are grouped as 7 strands of 1×19 wires each – twisted together. In a 7×19 cable, six 1×19 strands are wrapped around a 1×19 center (core). 7×19 is the most flexible construction you can have in cable. Like the 7×7, it has a high cycle life but a lower breaking strength.(could be used for ballustrading but is mainly used on cranes and winches where the highest flexibility is required and the maximum stretch co-efficient can be accommodated).

…Simply put, for a given diameter, the more fibers that are twisted to make a strand, and the more strands in a cable, the more flexible the wire rope becomes.

…In conclusion, the more wires twisted to make a strand, the more flexible is the strand of wire because it deforms/bends without damage. More details are also available Here … and if you are STILL interested – Further information is available at this Wiki Page