The Wire Rope Tensile Strength reported in terms of Minimum Breaking Strength (MBS). It achieves this rating based on destruction testing at the factory. In general – every batch will exceed its rating by some amount. This is done for safety purposes. A more detailed discussion of Certification and Mill Certificates is available HERE.

Please note that MBS is NOT the safe working load (SWL) or maximum working load (MWL) that the wire is rated at for a given purpose. Basically, the SWL depends on the MBS and a safety factor chosen by the Design Engineer. A further explanation of the SWL is available HERE.

MBS Factors

Some wire is coated, and some is naked 🙂 The MBS of a wire is not affected by a coating in any meaningful way – it depends on the following Factors (Note: for a more detailed discussion – simply click on our Wire Rope Specification Overview:

- Base material (e.g. galvanised steel vs stainless steel);

- Grade (e.g. AISI 316 vs 304; and Various Grades of Galvanised)

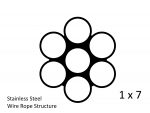

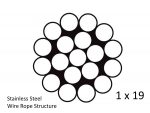

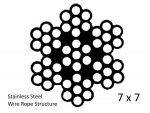

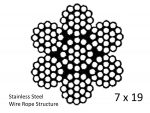

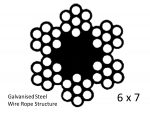

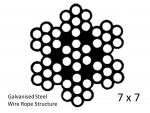

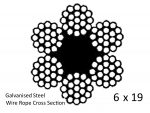

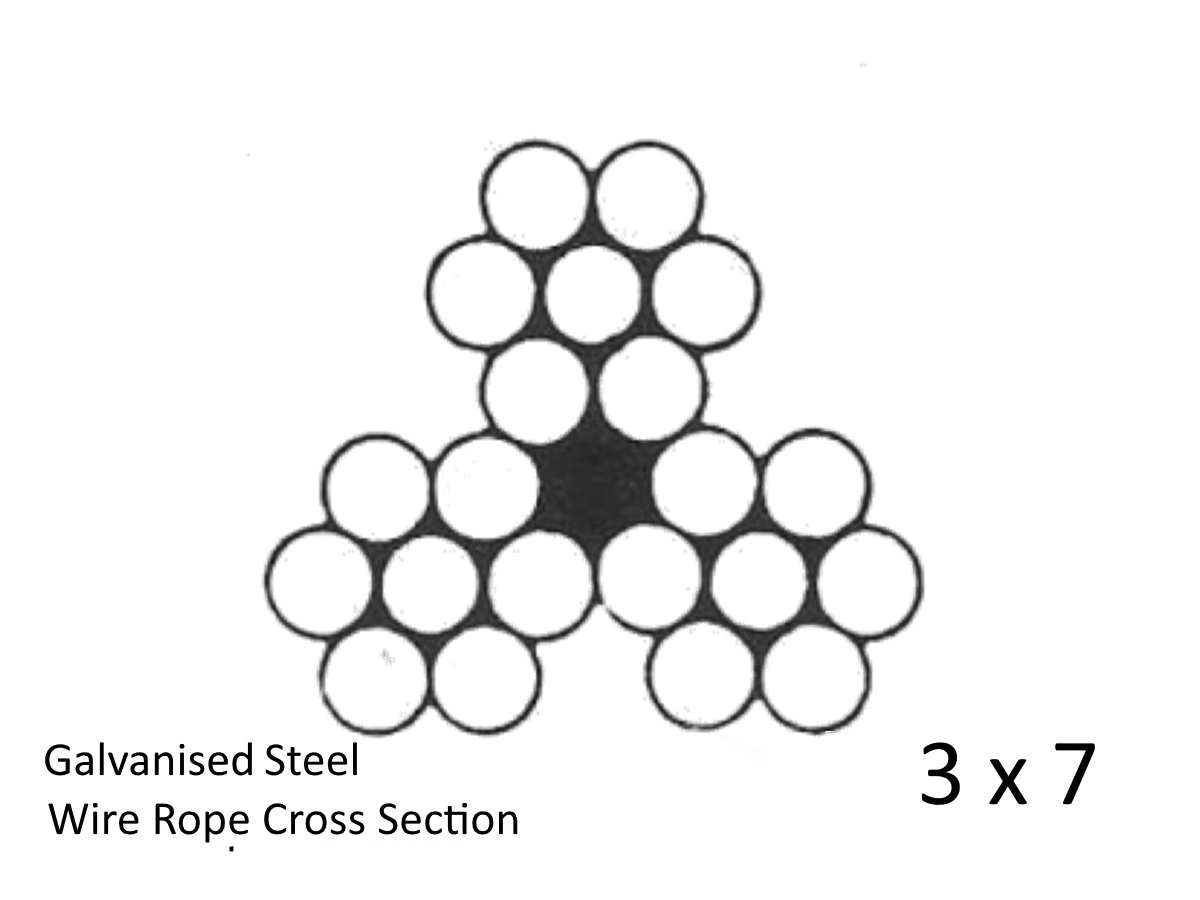

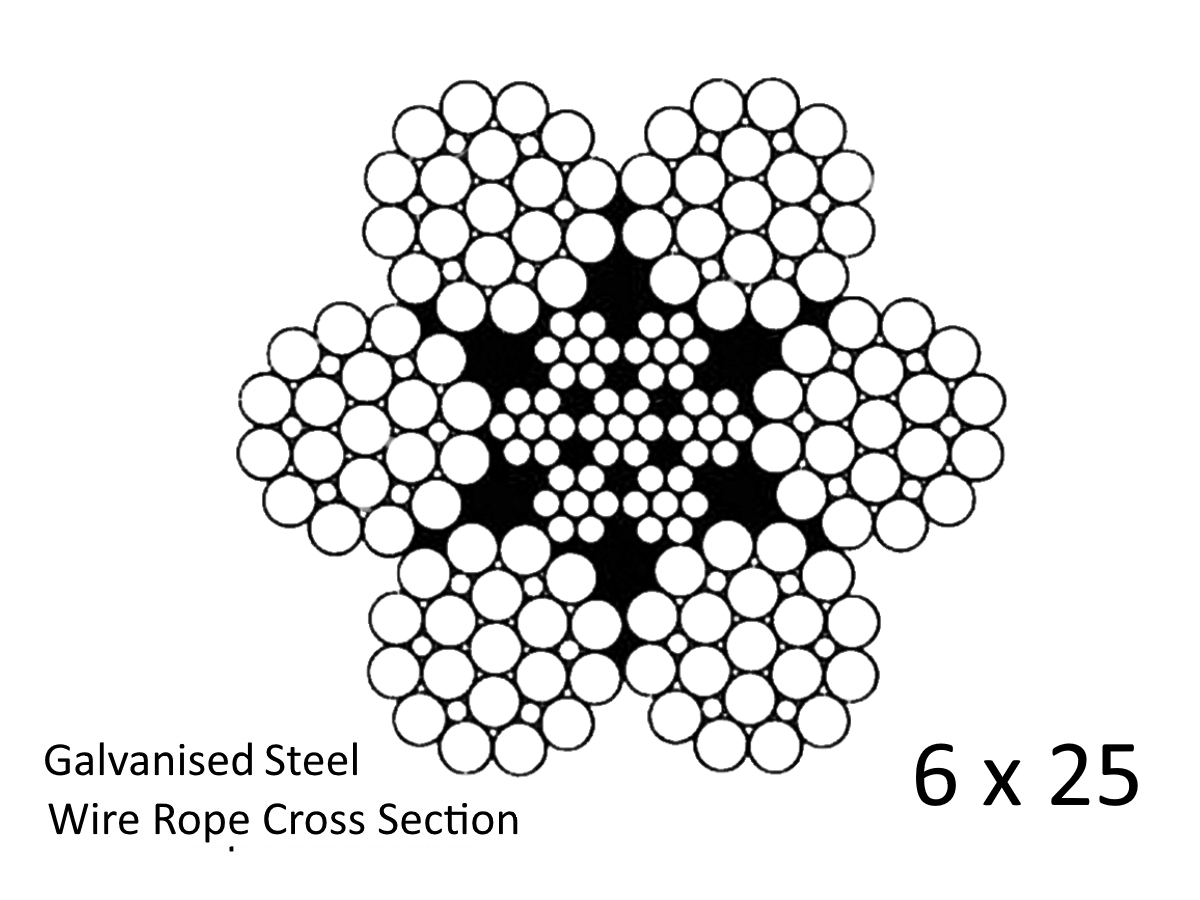

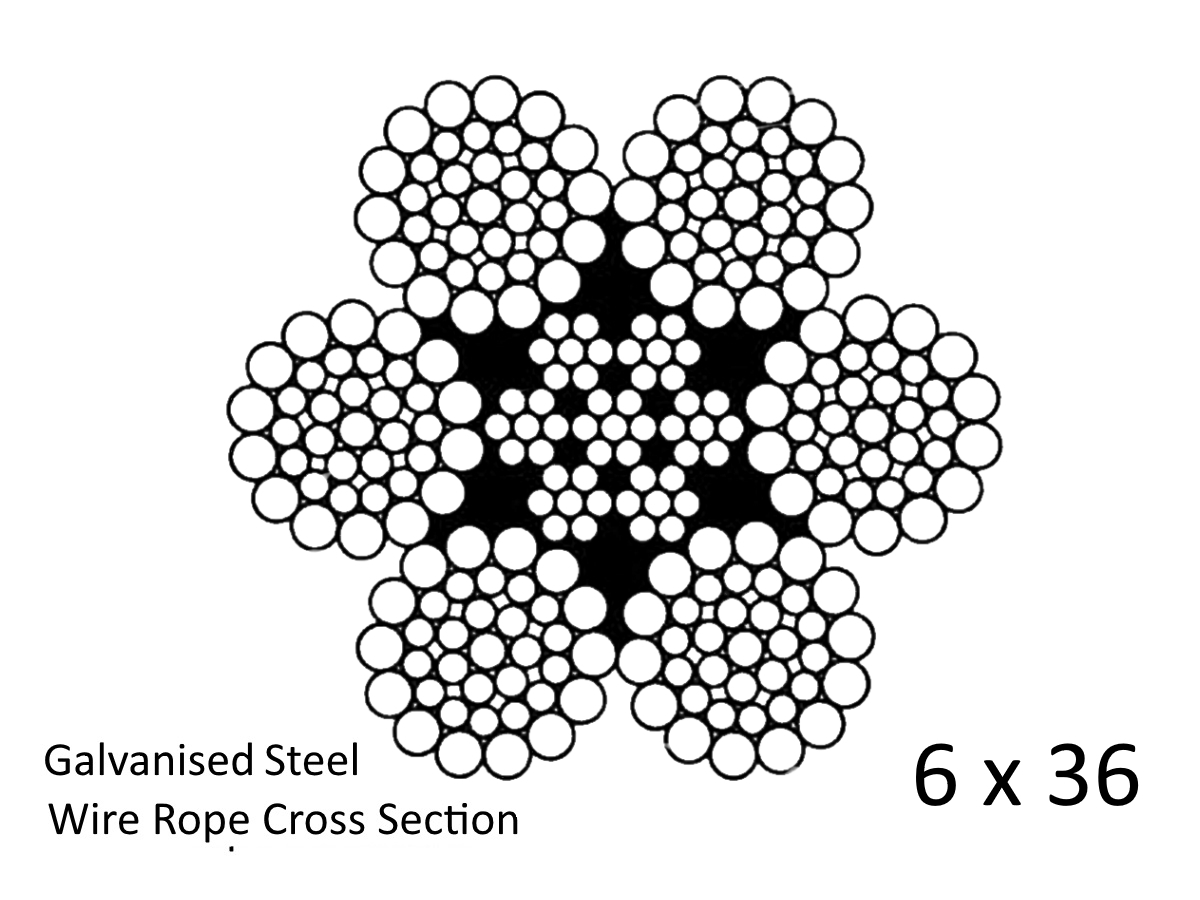

- Structure (e.g. 1×19 vs 6×36)

- Core (e.g. FC vs IWRC) and

- Diameter