Why is G316 Stainless Steel the Best Material for Wire Balustrades?

Pretty simple really- Stainless Steel lasts a VERY long time and looks awesome…

Why is it worth using Marine Grade Stainless Steel?

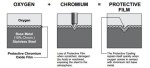

For severe environments such as high exposure to the elements, chemicals and solvents – and one of the most difficult is a marine or coastal location. With Stainless Steel Wire Rope, there are many grades – and the two you will most often run into are 304 and 316. Both of these grades can be legitimately called ‘Stainless Steel’ and share certain characteristics – but its the differences that count most!

What is the difference between G304 and G316 Stainless Steel Wire and Fittings?

Type 316 (or Marine Grade or G316) is also austenitic, non-magnetic, and thermally nonhardenable stainless steel like Type 304. The carbon content is held to 0.08% maximum, while the nickel content is increased slightly. What distinguishes Type 316 from Type 304 is the addition of molybdenum up to a maximum of 3%. To keep it simple 316 is simply a higher grade made to deal with anything mother nature can throw at it.

So 304 is good and 316 is better for resisting corrosion. On the other hand, 316 is more brittle – so fasteners (rivets and screws) are made of 304 to avoid breakage. This all makes sense as the bulk of the wire is exposed to the elements whereas the fasteners are buried in the structure.

What is the “best” 316 Stainless Steel?

Yes, you CAN do better than “plain old 316”. There is a variety of different types/alloys of 316 stainless steel – think of them as ‘sub-grades’. Some common types within the 316 Grade are the L, F, N, H, and Ti variants. Each is slightly different, and each is used for different purposes. We will focus on the L and the Ti versions. as both offer greatly improved corrosion resistance in non-exotic (natural world) deployment scenarios.

The “L” designation means 316L steel has less carbon than 316. AISI 316Ti stainless is a titanium-stabilized version of Type 316 molybdenum-bearing austenitic stainless steel

Some have made claims of the superiority of 316L stainless verses 316Ti. The simple truth is 316L and 316Ti are both excellent products. 316L has virtually the same amount of Titanium for high temperature stability as 316Ti but it also includes Molybdenum. This is what gives 316L greater corrosion resistance against low temperatures.