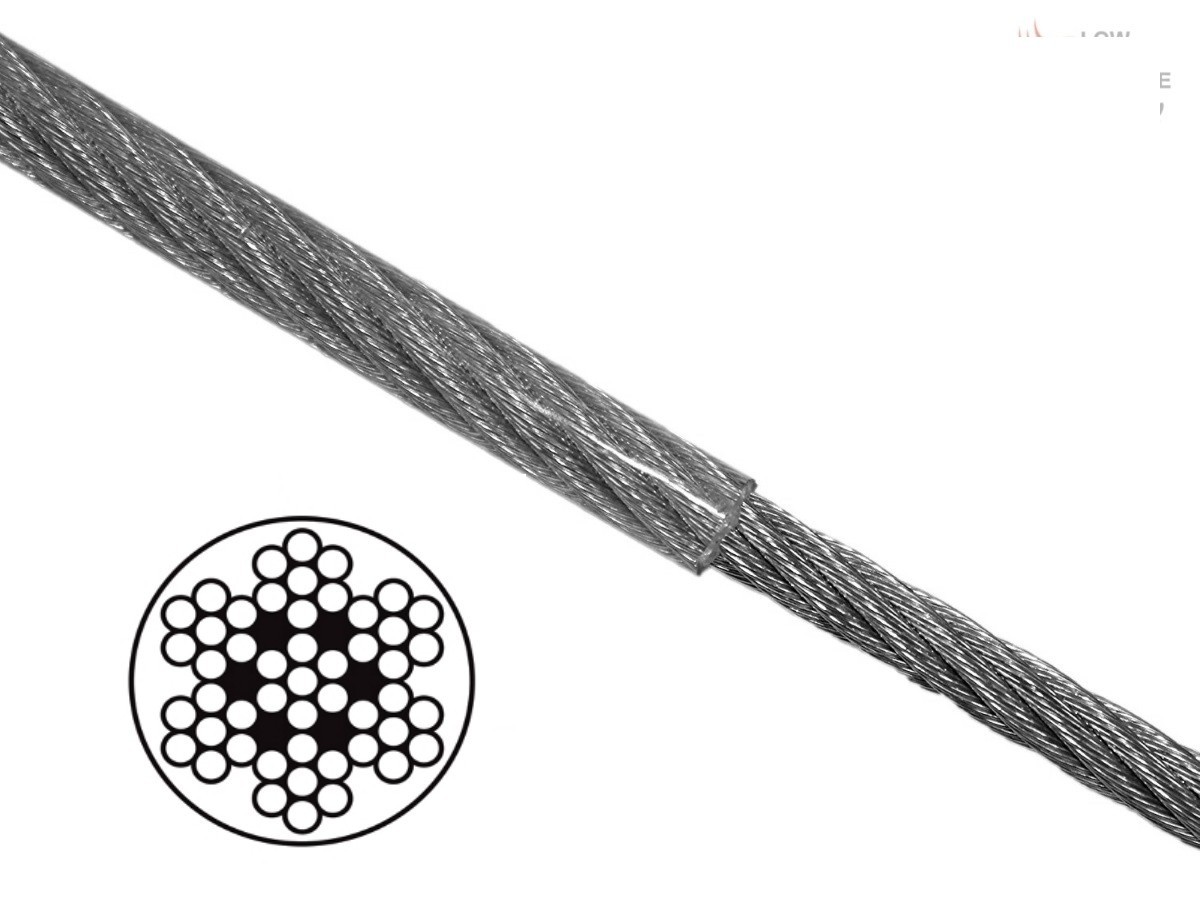

3.2mm 7×7 G316 Clear Coated Stainless Steel Wire Rope

Description

3.2mm Clear Coated 7×7 G316 Stainless Steel Wire Rope is primarily used in off shore fishing, hanging/display, shop fitting, industrial design and control cables. The 3.2mm 7×7 G316 Stainless Steel Wire Rope core has a Clear Coating. The wire has virtually no stretch and mid range flexibility. The flexibility and coating of the wire means it handles easily. The coating keeps is secure from fraying. As a result, it best Manually Swaged with Copper Ferrules. Both Professionals and DIY guys choose this wire for projects. Usage of the wire suits fittings for 3.2mm. Tensile Strength (MBS) = ~703.6kg

Usage: This 3.2mm Clear Coated 7×7 G316 Stainless Steel Wire Rope has a cumulative diameter of ~5.0mm. We recommend this wire with Thimble and Ferrule fittings. Additional uses include: Picture Rail, Shop Fitting, Presentation structuring, Light Rigging, Tagging and Security Wire.

Length of Wire: Use combinations of the offered lengths to get the desired total length. For example – choose a quantity of “8” of the 10M length to select a single length of 80 Metres. We cut and ship all Wire Rope orders as a single length. As a result, each wire order is packed as a coil or a reel depending on length and all are factory wrapped and sealed. A requirement of less than 100M on a reel needs a special order (please phone first).

Quality: All Low Cost Wire products meet our strict ISO Quality Standards. Likewise, our Stainless Steel Wire is AISI Mill Certified at manufacture. Our wire rope delivers the optimal balance between high tensile strength, fatigue resistance, abrasion resistance, and structural stability. Finally, our process provides a special treatment for a bright and smooth surface on the wire and cable. As a result, this delivers a truly top-shelf, long lasting product that will look new for ages…

Additional information

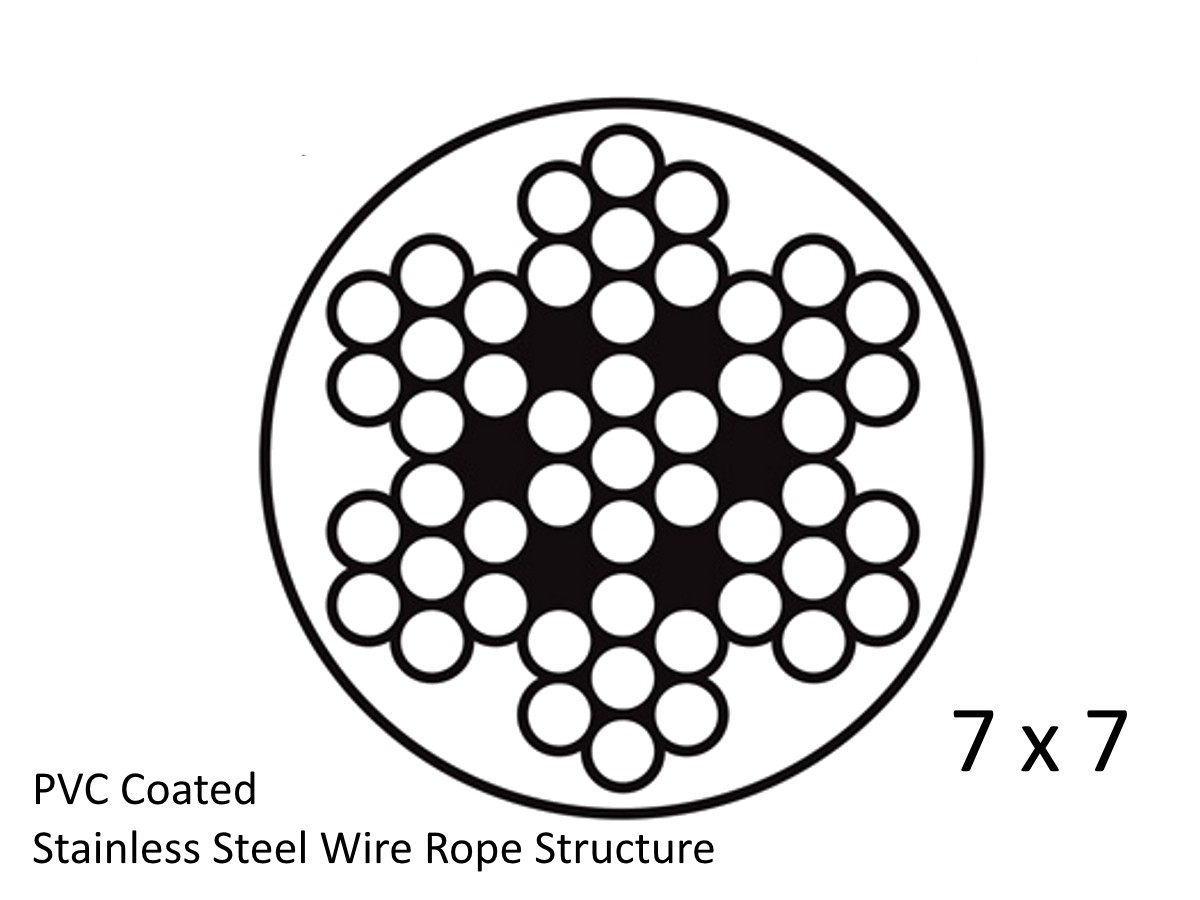

| Coating | PVC |

|---|---|

| Length | 1M, 10M, 100M, 305M |

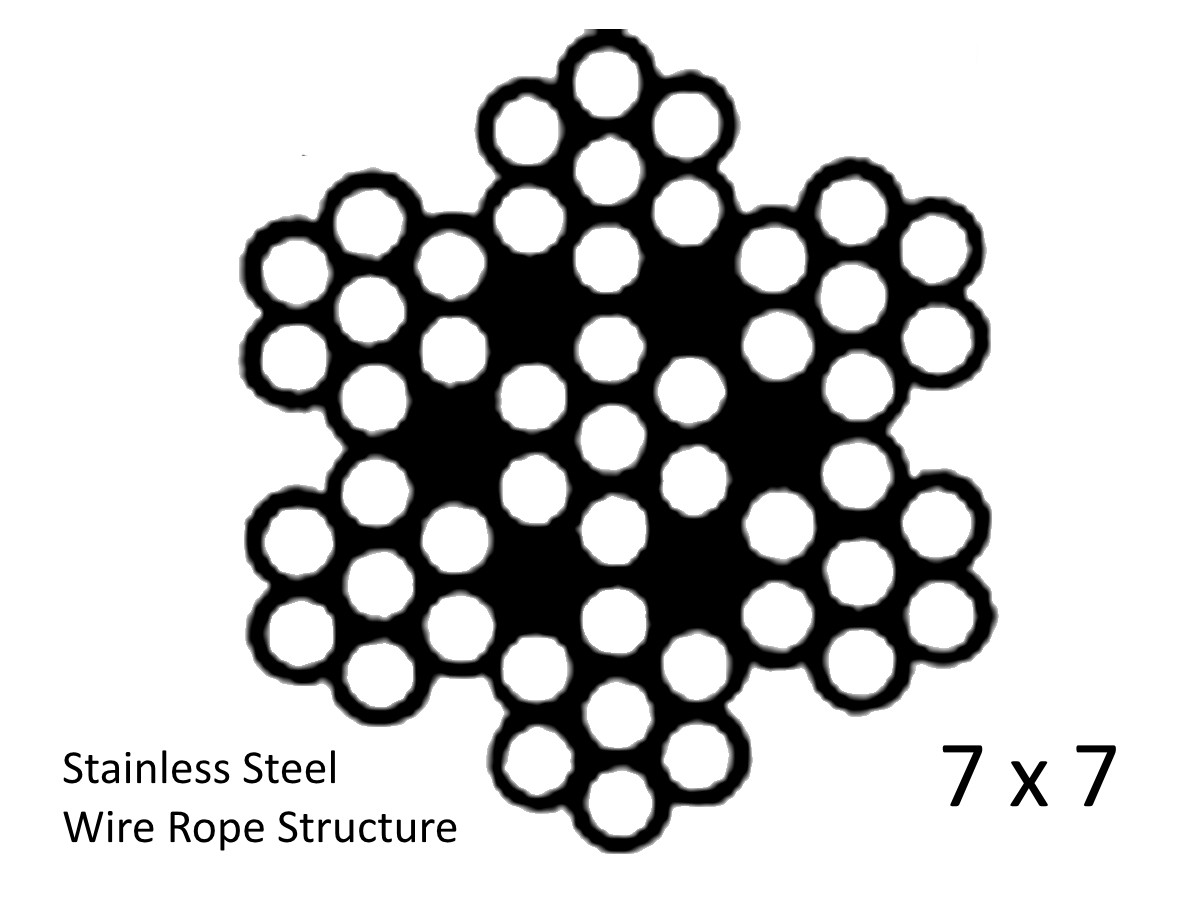

| Structure / Construction | 7×7 |

| Wire Diameter | 3.2mm, 4.8mm |

| Material | Stainless Steel |

| Grade | 316 / A4 |

| Color | Clear (Translucent) |

| Flexibility | Mid |

| Core | WSC |

| Lay | RHOL (Right Hand Ordinary Lay) |

| MBS (Tensile Strength) | 703.6 kg |

| Brand | Low Cost Wire |